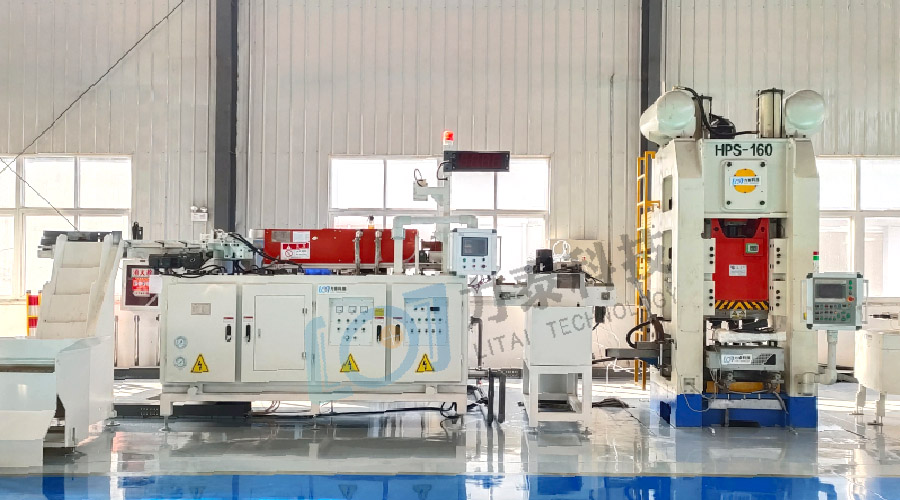

The overall layout plan for the hot forging nut production line of Nanjing Litai Technology

发布时间:

2025-04-17

In modern industrial manufacturing, the hot forging nuts, as key fasteners, their production efficiency and quality directly affect the reliability and safety of the equipment. Nanjing Litai Technology, relying on over 30 years of technological accumulation in the field of forging automation, has launched an intelligent hot forging nut production line layout solution. By optimizing the entire process of feeding, heating, and forging, it achieves high-precision and high-stability production of nuts. The following are the core design of the entire line:

1. Intelligent Feeding System: Precise feeding and dynamic sorting

The above translation is accurate and natural, following English expression habits.

The entire line adopts fully automatic hydraulic bucket elevators, which can achieve continuous lifting and intelligent sorting of bar materials. Through the synergy of the vibrating plate and the sorting channel, the bar materials enter the feeding track in sequence according to the preset direction, avoiding efficiency loss caused by manual intervention. The system supports compatibility for multiple specifications of bar materials and is equipped with sensors to monitor the feeding status in real time, ensuring production continuity.

II. Medium-frequency Induction Heating: High Efficiency, Energy Saving and Precise Temperature Control

In the heating process, a customized medium-frequency induction heating device is adopted. To meet the local heating requirements of the nut blanks, the coil design and power regulation are optimized. The bar materials pass through the induction zone at a constant speed. The heating duration, temperature and range can be precisely controlled by the PLC system. This technology achieves the advantages of fast heating and less oxidation decarburization. The temperature uniformity error of the blank after heating is controlled within ±5℃, providing stable blanks for subsequent forging.

III. High-pressure Scouring Technology: Enhancing Surface Quality and Mold Life

After heating, the bar materials pass through the high-pressure water descaling system, where the surface oxide scale is removed by the high-speed water flow. This equipment adopts a modular design, allowing for adjustment of the nozzle angle and water pressure according to the size of the billet to ensure thorough descaling without damaging the base metal. The descaled billets directly enter the conveying track, eliminating the need for manual handling, reducing pollution risks, and prolonging the service life of the molds.

IV. Bilateral Manipulator Cooperative System: Multi-station Dynamic Forging Pressing

The entire production line is equipped with dual-position servo mechanical arms to achieve full-process automation for the handling, flipping and forging of billets. The mechanical arms are equipped with a high-precision force control system, which can dynamically adjust the clamping force and transfer speed according to process parameters. The bilateral mechanical arms and multiple servo screw press machines work collaboratively, and through mold combinations, continuous processing at multiple stations such as roughing, pre-forging and forming is realized. The graphite lubrication system automatically sprays lubricants to reduce mold wear and improve the surface finish of the forgings.

V. Intelligent Forming and Quality Control: Full-process Digitalization

The final forging station adopts a servo screw press machine, which has precise energy control and fast response speed. It supports one-click operation to complete the entire hammering process. The formed nuts enter the inspection station through an automatic conveying chain. An integrated vision recognition and size measurement system is adopted to remove defective products in real time. The entire line is equipped with a data acquisition system, which can trace the process parameters of each link and achieve quality control throughout the product's life cycle.

Related News