Forging descaling: The core factor for ensuring the quality of forgings

发布时间:

2025-04-22

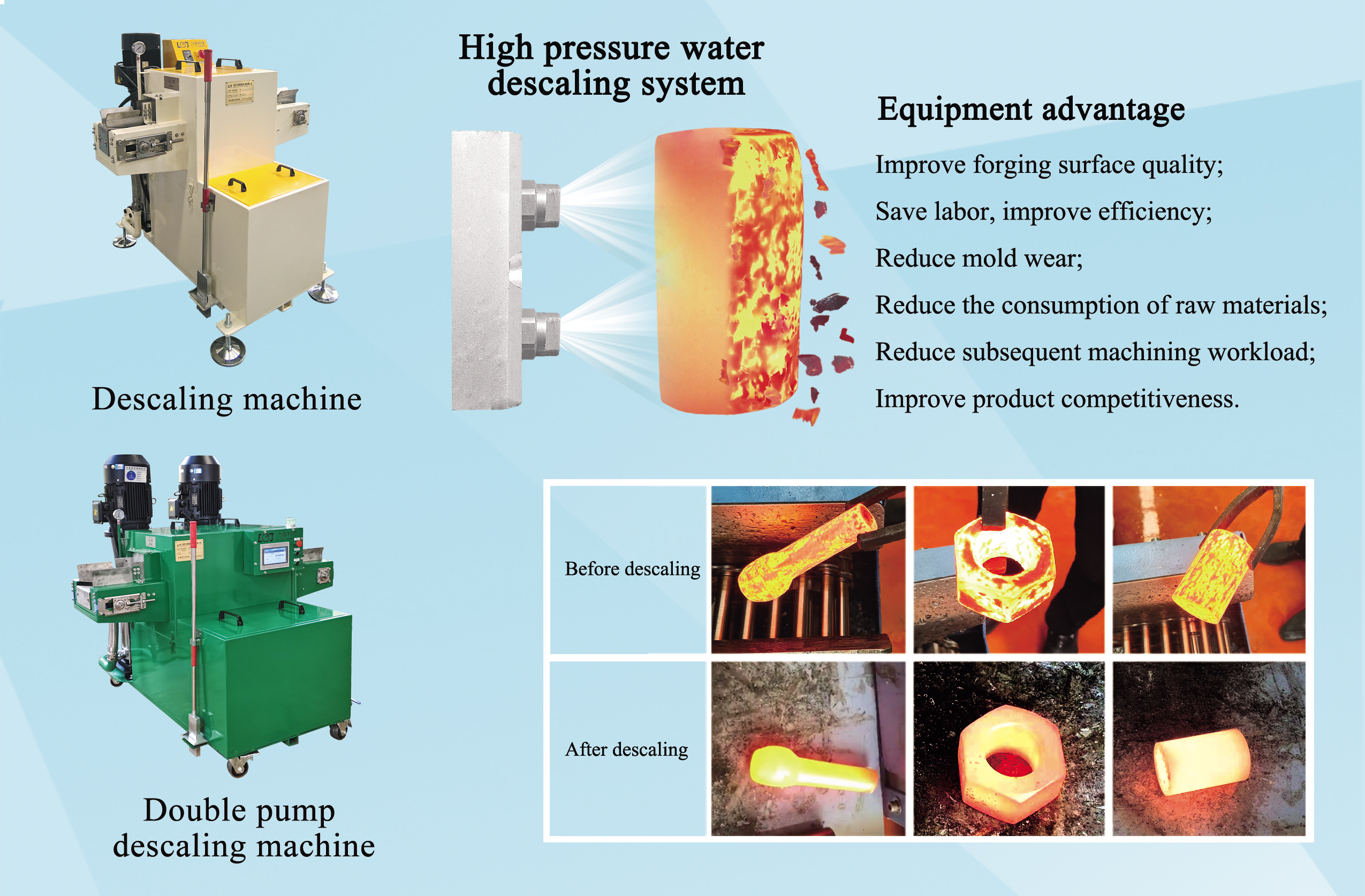

In the field of forging, the descaling process is regarded as a crucial step to ensure the quality of forgings. When metal billets undergo forging under high-temperature conditions, an oxide scale forms on their surfaces. If these oxide scales are not promptly removed, they will have a significant impact on the quality of forgings, the lifespan of molds, and production efficiency. This article will deeply analyze the importance of descaling processes, common methods, and key points of parameter control, providing valuable references for the forging industry.

The presence of oxide scale can lead to a series of problems. Firstly, it will cause damage to the surface quality of the forgings. During the forging process, the oxide scale may embed into the surface of the forgings, resulting in defects such as pits and pockmarks on the forgings, thereby reducing the surface smoothness and accuracy of the forgings. Secondly, the oxide scale will accelerate the wear of the molds.

During forging, the friction between the oxide scale and the die will cause scratches and wear on the die surface, shortening the service life of the die and increasing the production cost of the enterprise. Besides, the oxide scale will also affect the mechanical properties of the forgings. It will impede the heat transfer, cause uneven metal deformation, and thus lead to differences in the internal structure of the forgings, affecting their mechanical properties such as strength and toughness. Finally, the oxide scale will also reduce the production efficiency. In the subsequent processing steps, extra time and effort are required to deal with these oxide scales, increasing the complexity of the production process.

In the current competitive environment of the forging industry, the descaling process, as a core link to ensure the quality of forgings, is of no doubt of great significance. By choosing the appropriate descaling method and precisely controlling the process parameters, enterprises can effectively remove the oxide scale, improve the quality of forgings, extend the service life of molds, reduce production costs, and enhance production efficiency. In the future, with the continuous development of technology, the descaling process will also develop towards a more efficient and environmentally friendly direction, providing strong support for the sustainable development of the forging industry.

Related News