The application degree of induction heating furnaces in the forging industry

发布时间:

2025-06-30

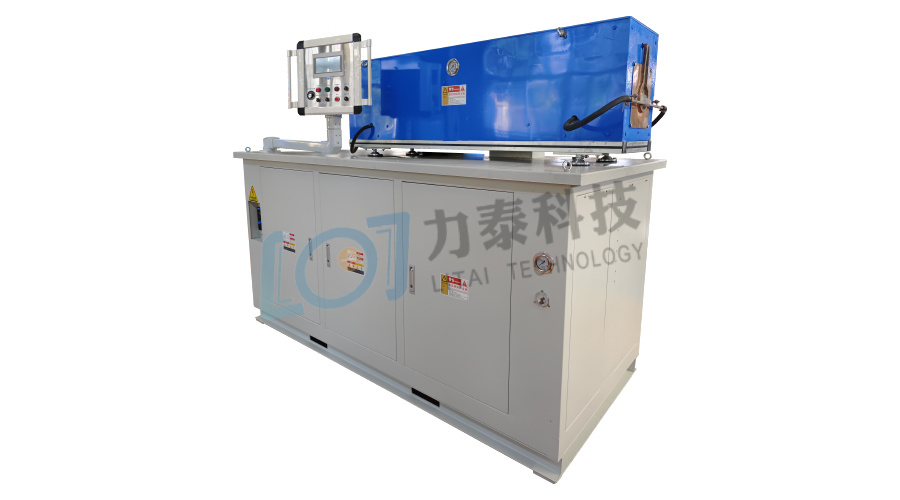

In the development process of the forging industry, the induction heating furnace, with its unique advantages, has occupied an extremely important position and its application scope has become increasingly extensive and in-depth. Litai Technology, as an important member of the industry, has a profound understanding and practical experience in the application of induction heating furnaces.

The induction heating furnace can quickly heat the workpiece to the required forging temperature, significantly improving production efficiency. When forging the connecting rods of automotive engines, the traditional heating method may require a longer time to reach the required temperature. However, the induction heating furnace, utilizing the principle of electromagnetic induction, enables the workpiece to heat itself rapidly. Within a few minutes, it can reach the appropriate temperature, significantly shortening the heating cycle and meeting the demands of large-scale production. This rapid heating characteristic has been fully verified in many forging enterprises served by Litai Technology, greatly enhancing the production capacity of these enterprises.

In terms of heating uniformity, the induction heating furnace performs exceptionally well. It ensures that the heat penetrates evenly into the interior of the workpiece, avoiding overheating on the surface and insufficient internal temperature. For the forging of complex-shaped gear blanks, uniform heating guarantees uniform deformation of each part during the forging process, reducing defects such as cracks and folds, and improving product quality. Lifte Technology fully understands its significance and provides customers with induction heating furnace solutions that effectively help enterprises increase product qualification rates and enhance market competitiveness.

Induction heating furnaces have significant advantages in terms of energy conservation and environmental protection. They directly heat the workpieces, reducing heat loss through heat transfer. Compared to traditional coal-fired or gas-fired heating furnaces, their energy-saving effect is remarkable. At the same time, there is no open flame or smoke emission, which improves the working environment in the workshop and aligns with the current environmental protection concept. Lietai Technology follows this trend and helps forging enterprises achieve efficient production while meeting the goals of energy conservation and emission reduction, promoting the green development of the industry.

Related News