Electric Screw Press Hot Forging Machine Forging Line Die Forging

Keyword:

Electric screw press

Forging press

Electric screw press machine

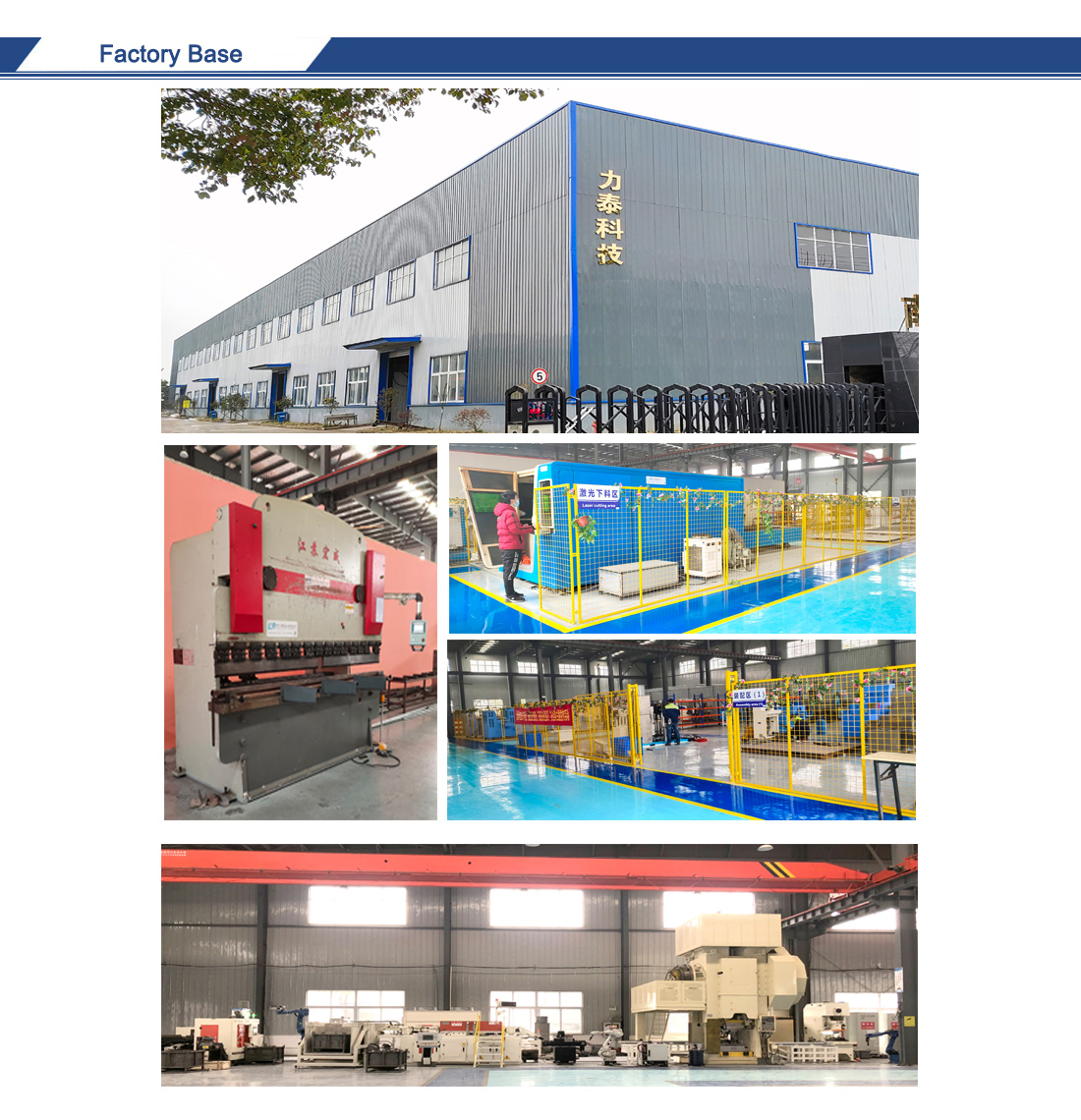

Having been deeply involved in the forging industry for many years, Litai Technology is committed to providing full process supply chain services for forging enterprises, including supporting equipment supply chain, strategic planning of automated production lines

Tel:

- DESCRIPTION

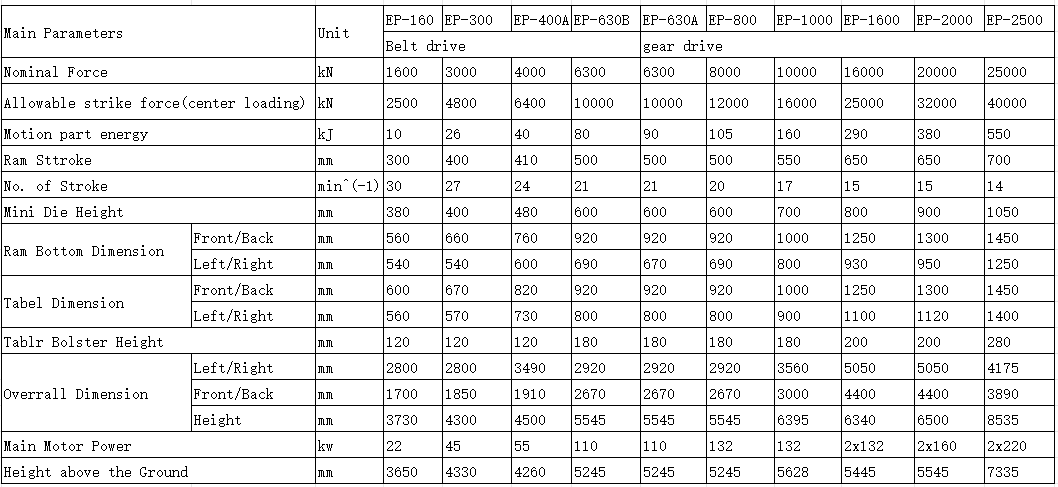

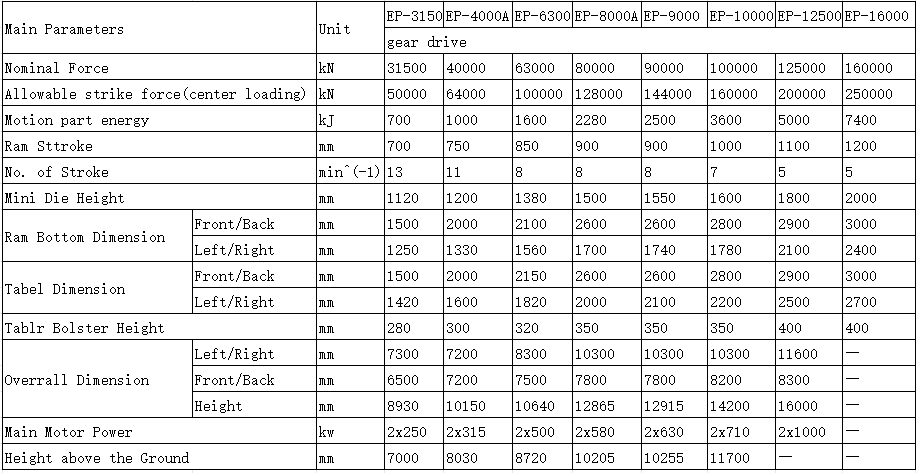

- PARAMETERS

-

- Commodity name: Electric Screw Press Hot Forging Machine Forging Line Die Forging

The electric screw press is the equipment used in forging industry. The screw press has the characteristics of large universality, simple structure, easy adjustment and maintenance, no bottom dead point of the slider, easy die design and high forging accuracy. Suitable for all kinds of precision forging, finishing, fine pressing, stamping, calibration, calibration equal process. Electric screw press can be used not only for hot forging, but also for precision forging and finishing. It can be applied to the pressure welding process of stainless steel double bottom pot, and can be applied to the precision forging of titanium alloy blades and other blades.

1. Accurate energy control, fast response speed

The pressure energy can be set in advance simply and accurately, and the accurate and precise pressure without input and error is repeatedly implemented for each stroke to ensure the uniformity of products. Servo motor direct drive, no clutch reaction time, running response speed is fast.

2. Reasonable structure, more uniform products

Because there is no structural dead center, there is no need to worry about excessive load due to excessive material size or uneven heating temperature, as well as slide lock (bite stop due to overload). Moreover, the same material can be repeatedly pressed with different forces to gradually deform and implement successive forging.

3. Fast forming speed, prolong the life of the mold

The slider speed of the screw press is very fast when it is close to the bottom dead point, and the time of extrusion material of the mold is very short, and the processing can be completed instantly before the hot material is cooled. The contact time with the mold is short, and the mold temperature changes little, which greatly extends the life of the mold.

4. Simple structure, low maintenance cost

Servo motor direct drive, simple structure, fewer parts, low maintenance and maintenance costs. Usually run, without brakes, the motor itself can stop the slide. The mechanical brake only does double protection, and is used in emergency times such as power failure, and the service life of the brake disc is extremely long.

5. The energy process is controllable and has a wide range of applications

The servo CNC press can set the pressure energy, so that the slider first accelerates the descent, and then decelerates to press the material at the set energy. Large tonnage presses can also forge small parts, and the processing time per unit stroke is basically unchanged. Both large and small, has the effect of twice the result.

6. High efficiency, energy saving, reduce production costs

The servo motor rotates only when the machine is started (the friction mode is that the motor is continuously running). The comprehensive energy-saving effect is about 55% energy-saving compared with the previous friction press.

7. Stamping molding, high pressure energy

The pressure method is the same as the previous friction press, the flywheel energy is fully consumed and pressurized, which is the instantaneous stamping pressure method, so the pressure energy generated is very high.

8. Low noise, low vibration

The pressure is produced within the frame. Compared with the ramhammer, there is no excessive ground vibration, and the ground foundation works can be cheaply implemented. The noise and vibration are much lower than the impact hammer.

-

Related Products

Messages