Fully Automatic Bolt Making Machine bolt hot forging prodcution line

Keyword:

forging bolt production line

forging production line

Nuts And bolts making line

Nut Bolts Making Machine

Having been deeply involved in the forging industry for many years, Litai Technology is committed to providing full process supply chain services for forging enterprises, including supporting equipment supply chain, strategic planning of automated production lines

Tel:

- DESCRIPTION

- PARAMETERS

-

- Commodity name: Fully Automatic Bolt Making Machine bolt hot forging prodcution line

Nanjing Litai Technology free to provide your enterprise automation one-stop solution. With the development of modern industry, the market has higher and higher quality requirements for bolts, and bolts, as one of the important components of fasteners, have a wide range of uses and a huge amount. However, at present, the production of hot-forged bolts all use the traditional production method, relying on manual completion of blank feeding and workpiece delivery, this production method is low efficiency, product quality is unstable, and production costs are also greatly increased with the rise of workers' wages.

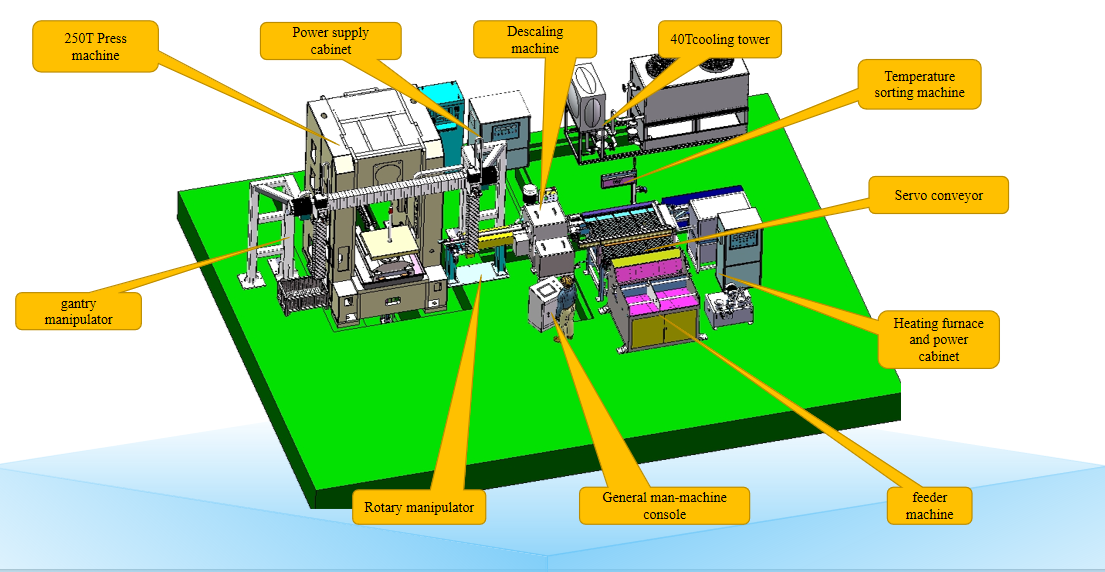

The key technology of automatic transformation of bolt forging production line of Litai is to realize automatic feeding of blank bar material and automatic conveying of blank material between forging stations. The assembly model of the automatic forging production line is established, and the test prototype of the automatic conveying system is set up. Through a series of on-line debugging and test design, a bolt is produced by 2-3s. It is very important to improve the efficiency of bolt forging production, improve the quality of hot forging bolt, reduce the production cost and labor intensity of workers.This production line includes below equipmet :

1. Heating Forging Feeding machine

The hopper will turn the raw materials into the elevator, and the elevator will automatically arrange the materials in an orderly manner, without the operator, and the elevator will orderly push the raw materials into the electric furnace for heating.

2. Induction heating furnace

Through scientific design, the height of the furnace is reduced, so that the maintenance of the whole line is simple and convenient, the overall appearance is beautiful, and the overall sense of science and technology of the forging production line is improved. Full digital control, with high control accuracy and high reliability, voltage and current double closed-loop control system, perfect protection system, high power factor operating characteristics, perfect external control interface, power start-up performance 100%.

3. Temperature sorting machine

Automatic temperature monitoring, three-way sorting, and selection of materials with qualified temperature; the distance from the conveyor link material port to the intermediate frequency furnace mouth can be adjusted so that the materials coming out of the intermediate frequency furnace can be pushed smoothly into the conveyor chain.

4.Descaling machine

The Descaling Machine for Hot Forging Piece Cleaning adopts the principle of high-pressure water descaling system, and the water pressure can reach 1.8-2.0mpa. It can effectively remove the scale of hot forged gears under high temperature while the cooling range of forgings can be controlled within 30 ℃. At present, this cleaning equipment has been widely used in China, and the improvement of forging surface quality has been recognized by the market.

5. Rotary manipulator After the bar material is passed through the descaling machine, the direction is smoothly adjusted by the Rotary manipulator to facilitate the manipulator to pick up and press

6. Automatic lubrication equipment

The lubrication workstation, based on the storage of release agents and the supply to automatic lubrication equipment, is a device designed with stainless steel plates. It separates lubrication and cleaning to achieve automatic lubrication and automatic mixing of cleaning fluids. It is also equipped with pressure sensors that can monitor pressure changes in real-time and respond accordingly. Additionally, it supports various functions such as self-cleaning and automatic washing. In conclusion, the Graphite Workstation is a comprehensive and efficient solution for lubrication and cleaning needs in industrial applications.

The Automatic lubrication equipment,Reducing the stickiness of the mold makes it easier for the product to be released from the mold. Serving to control the stroke, it is used for forging and mold release. Before forging, three spraying operations will be carried out: first spraying air, then spraying mold release agent, and finally spraying air again. The automatic lubrication equipment has a delicate and compact appearance, saving space, and adopts servo automatic lubrication.

7.Forging press machine

It is the absolutely necessary part in the forging process ,it has different tonnage according to the size and dimensions of the product, which can be customized production.

8.Gantry manipulator Through the manipulator to complete the bar material clamping, free hands, improve production efficiency

8.Mold shelt and Bolt mold

We can design the Mold shelt and Bolt mold for customers .

9.conveyor chain

Litai has eight years of experience in high-speed conveyor chain, conveyor chain design structure is reasonable, the material is hanging properly, the appearance is simple and atmospheric, and there are tow tracks. At the same time, it has a variety of optional functions such as counting, anti-buffering, feeding, air cooling and so on. High efficiency and energy saving, smooth transmission, low failure rate, greatly ensure the function and service life of the conveyor chain, to meet the various needs of the forging line.

Related Products

Messages