Litai steam air hammer air forging power hammer forging press for sale

Keyword:

forging air hammer

air hammer

air power hammer

air forging power hammer

Having been deeply involved in the forging industry for many years, Litai Technology is committed to providing full process supply chain services for forging enterprises, including supporting equipment supply chain, strategic planning of automated production lines

Tel:

- DESCRIPTION

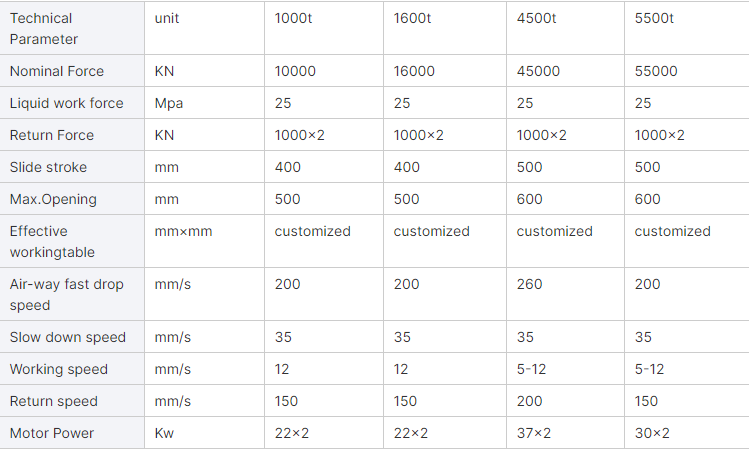

- PARAMETERS

-

- Commodity name: Litai steam air hammer air forging power hammer forging press for sale

Forging air hammer is mainly used to fee forging, drawing, upsetting, punching, hot shearing, forged welding, bending, torsion and swedge forge. One piece forging hammer and two pieces forging hammer can be assembled and trial run before leaving factory. The percent of pass of production(complete machines)leave factory is 100%.

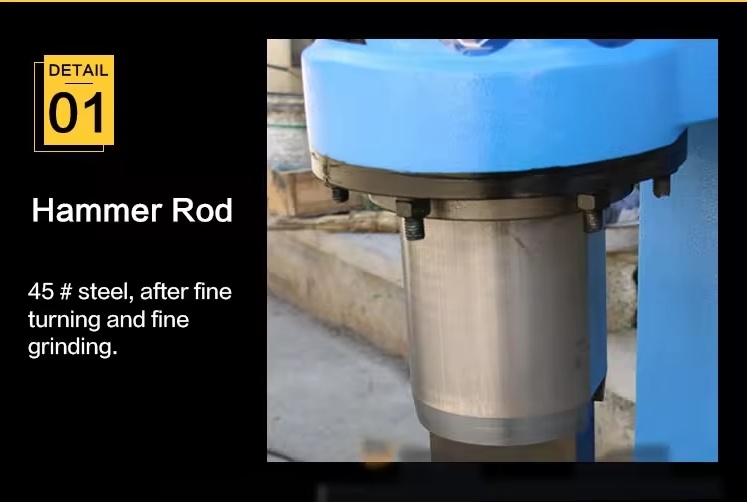

Air hammer is composed of hammer body, compression cylinder, working cylinder, transmission mechanism, control mechanism, falling part and anvil base, in fact, just like the outside of the iron.

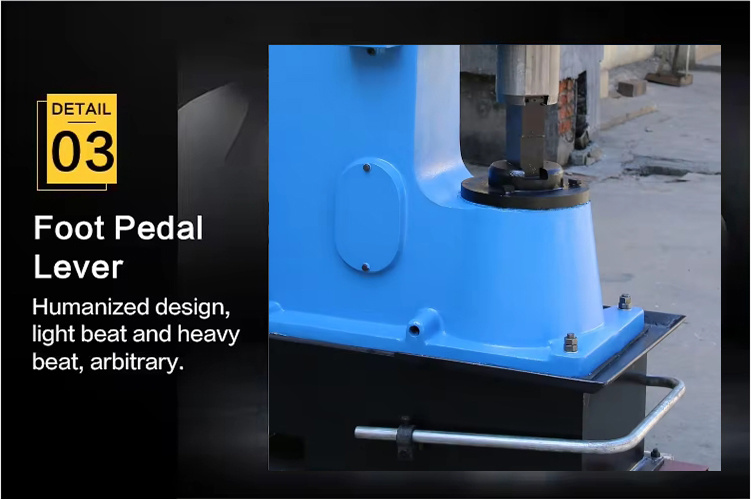

The working principle of the air hammer: The motor through the deceleration mechanism and crank, the connecting rod drives the compression piston of the compression cylinder up and down to produce compressed air. When the upper and lower airways of the compression cylinder are connected with the atmosphere, the compressed air does not enter the working cylinder, the motor is idling, and the hammer head does not work. The upper and lower rotary valve is operated by the handle or foot rod, so that the compressed air enters the upper or lower part of the working cylinder, and pushes the working piston to move up and down, thus driving the rise or fall of the hammer head and the upper steel to complete various striking actions. There are four modes of communication between the rotary valve and the two cylinders, which can produce four actions: lifting hammer, continuous play, downward pressure and idling.

1. Efficient striking power

The air hammer uses compressed air as power, so it can produce high speed and powerful striking force. It can easily cope with some high hardness, high strength materials, such as rock, steel and so on. By reasonably adjusting the pressure and flow of the air source, different effects can be achieved to meet the needs of different application scenarios

2. Precise control

The air hammer has good controllability, and the size and frequency of the striking force can be controlled by adjusting the parameters of the air source. This allows users to perform precise operation and control according to actual needs. Whether it is for fine machining or blasting, the air hammer can provide accurate and stable impact effects.

3. Energy saving and environmental protection

Compared to other power tools, air hammers use compressed air as a power source and do not need to burn any fuel, so they emit no pollutants. At the same time, compressed air is a renewable resource, the use of air hammer can reduce the dependence on non-renewable energy, to achieve the purpose of energy conservation and environmental protection.4. Multifunctional applications

Air hammer has a wide range of applications. It can be used in many industries such as metal working, quarrying, excavation and demolition. In metal processing, air hammer can be used for forging, mold repair and other processes; In the quarrying industry, air hammers can be used for rock breaking; Air hammers can easily break concrete and other hard materials during demolition work.

-

Related Products

Messages