Ultra-high pressure forging descaling machine billet descaler

Keyword:

Forging descaling machine

oxide scale forging machine

Descaling Machine

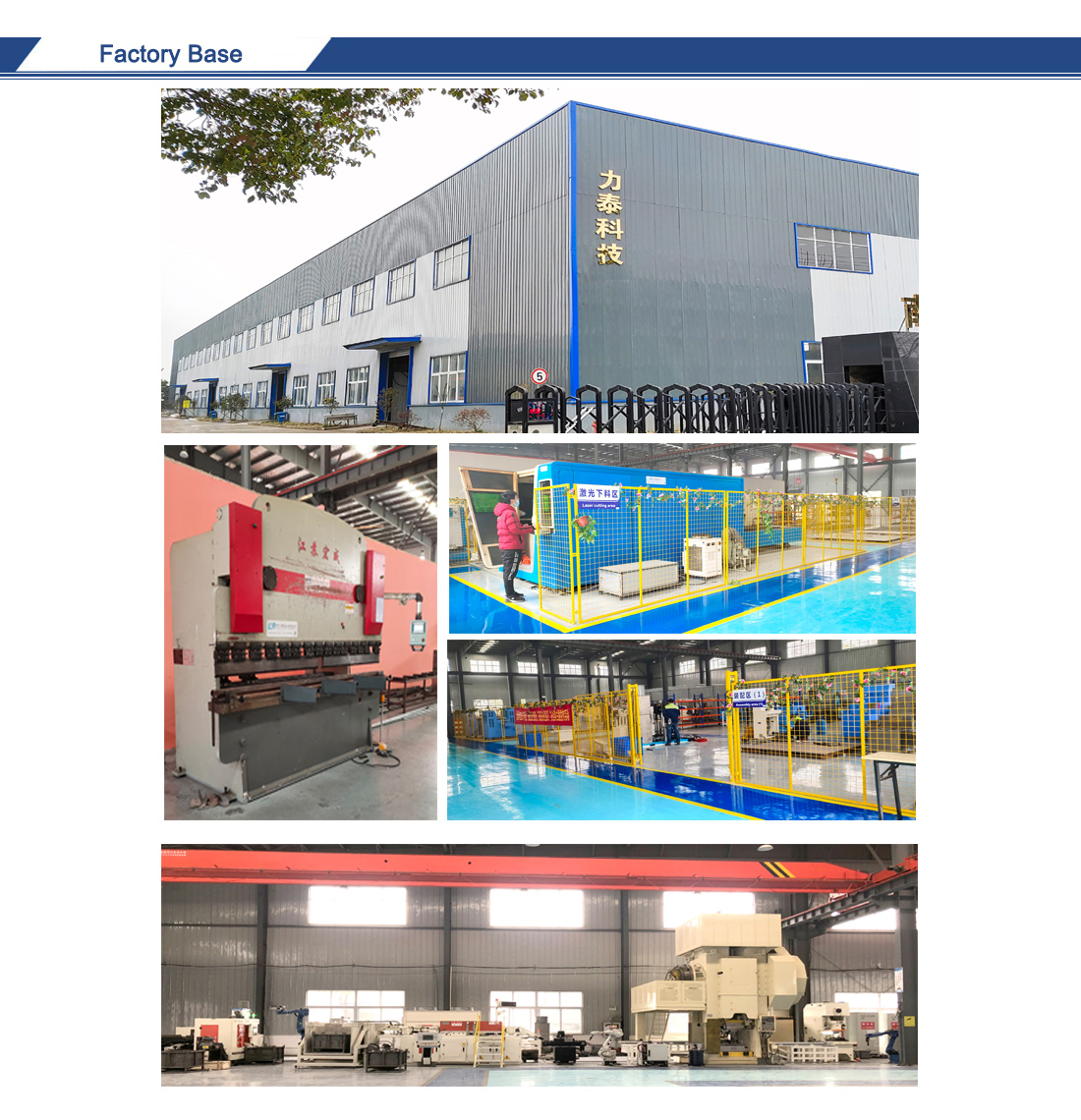

Having been deeply involved in the forging industry for many years, Litai Technology is committed to providing full process supply chain services for forging enterprises, including supporting equipment supply chain, strategic planning of automated production lines

Tel:

- DESCRIPTION

- PARAMETERS

-

- Commodity name: Ultra-high pressure forging descaling machine billet descaler

Ultra-high pressure forging descaling machine

The Ultra-high pressure forging descaling machine adopts the principle of high-pressure water descaling system, and the water pressure can reach 1.8-2.0mpa. It can effectively remove the scale of hot forged gears under high temperature while the cooling range of forgings can be controlled within 30 ℃. At present, this cleaning equipment has been widely used in China, and the improvement of forging surface quality has been recognized by the market.

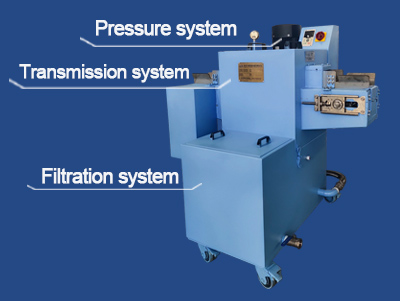

The Cleaning machine from Litai-forge, the main body of the equipment is composed of a pressure system, a transmission system and a filtration system. The three systems jointly use the principle of high-pressure water cleaning to complete the cleaning process of the forging scale.

The high-pressure water cleaning system is adopted and generated by the high-pressure water pump enters the cleaning nozzles which could be sprayed on the surface of the forging (or intermediate billet). The oxide scale has undergone the process of being cut, rapidly cooled and contracted, peeled from the base material, and washed away from the surface of the forging, thereby removing the oxide scale.

The cleaning machine is equipped with two water tanks. The water tank has a built-in filter screen and a net basket to form the filter system of the equipment to prevent oxide scale from entering the water pump and affect the service life of the equipment. At the same time, it is equipped with a magnetic shovel to clean the oxide scale in the water tank.

The frequency conversion motor and the chain constitute the transmission system, which is responsible for transporting the forgings for the cleaning process. The transmission speed of the chain can be adjusted to ensure that the temperature of the forgings after cleaning is small, which is conductive to subsequent forging.

1,The main body of the water tank is made of 304 stainless steel and body color can be customized

2,The exit and entrance adopt integral welding with high parallelism

3,Front and back built-in baffle, less splash, easy maintenance

4,Integral cover to protect pump motor

5,Compared with the conventional descaling machine, the flow rate is large, and it is suitable for the refractory oxide scale products6,The nozzle mounting seat is welded with stainless steel, which is easy to maintain

6,Comprehensive treatment of oxide skin, less lower the temperature

7,After removing the oxide scale, the metallographic structure of the product has no change

1. What kind of forging pieces is cleaning machine suitable for?

The cleaning machine is applicable to the hot forging production line. It can clean the oxide scale generated after heated by induction furnace and effectively improve the surface quality of products.

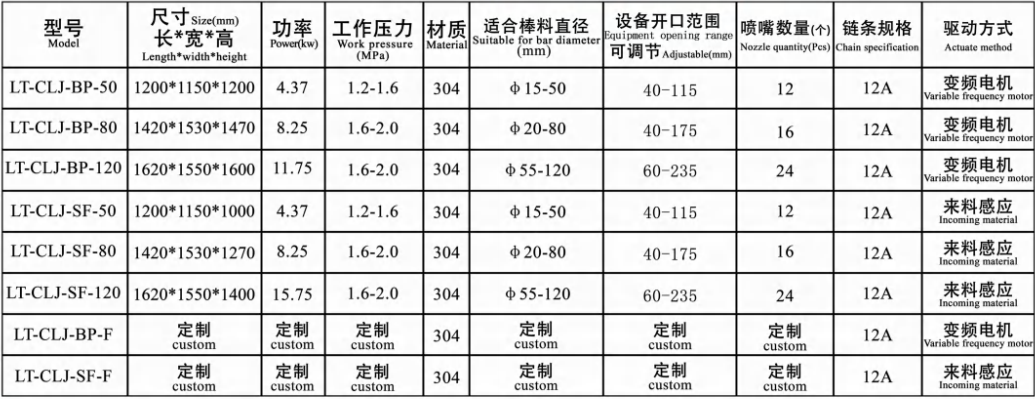

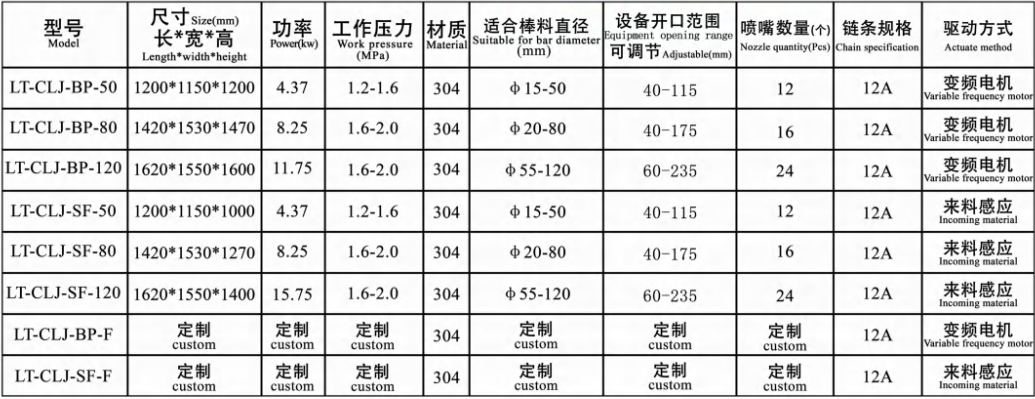

2. How to choose the model of descaling machine? Can it be customized?

You can select the corresponding standard model through the diameter of the round bar and the size of the billet after making. For details, please check the parameter navigation bar of the webpage. If there is a need for customization, we can also provide customized services according to the customer's raw material size and process.

3. How to daily maintain descaling equipment?

We will recommend that customers regularly clean the oxide scale in the water tank. You only need to use a magnetic shovel to remove most of the oxide scale. But also regularly replace the water in the water tank to ensure a normal filtration cycle.

4. Does the principle of high-pressure water cleaning change the metallographic structure?

This method has been tested by a third-party organization. The test report shows that there is no change in the metallographic structure before and after cleaning, which has no effect on the later process.

5. How effective is the descaling machine? Is there a reference video for descaling equipment?

Litai-Forge has served more than a thousand forging factories in China, and received a large number of market feedback results. Regarding the on-site use of the equipment, please click into the video as below for more information.

-

Related Products

Messages