How to select the appropriate equipment for removing oxide scale in hardware tools?

发布时间:

2025-07-24

In the production of hardware tools, choosing the right equipment for removing oxide scale is of vital importance for enhancing production efficiency and product quality. The following are several key aspects that need to be considered when making the selection:

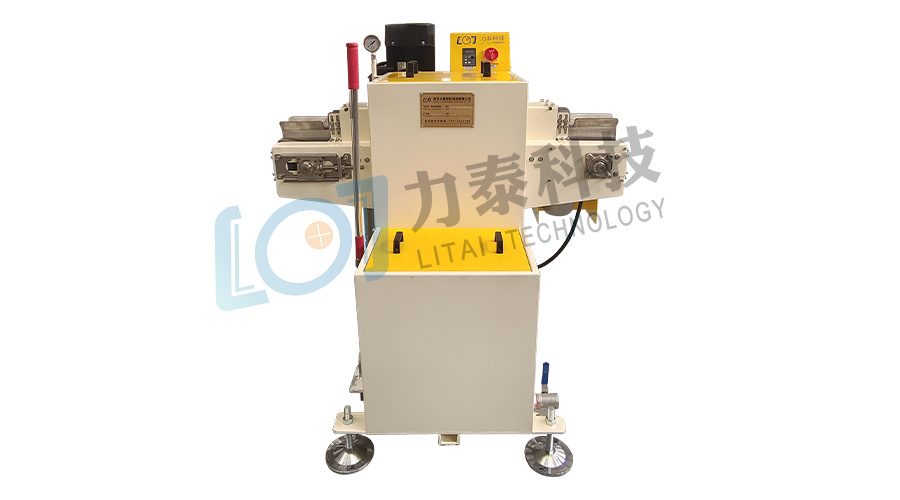

Firstly, pay attention to the compatibility between the equipment and the types of hardware tools. Different types of hardware tools, such as wrenches, screwdrivers, pliers, etc., have differences in shape, size and material, and thus have different requirements for the descaling equipment. For example, tools with complex shapes need the equipment to be able to spray in all directions to ensure that every corner of the oxide scale can be removed; while small and precise tools require the equipment to have an appropriate spraying force to avoid damaging the tools. The descaling equipment of LITAI Technology can be adjusted according to the characteristics of different hardware tools, and has strong adaptability.

Secondly, evaluate the descaling efficiency and effectiveness of the equipment. Production efficiency is a key concern for enterprises, and the processing speed of the equipment needs to match the rhythm of the production line. High-quality equipment should be able to remove the oxide scale within a short period of time. For example, the equipment of LITAI Technology can process one workpiece in 3-6 seconds. At the same time, the descaling effect must be thorough. The surface of the processed tools should be free of residual oxide scale and no new damages should occur, ensuring that the surface of the tools is smooth and flat, and not affecting the subsequent processing.

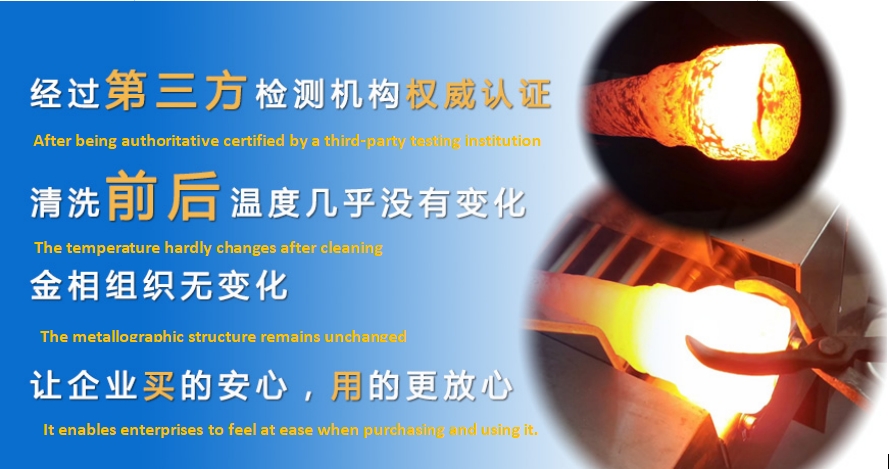

Furthermore, it is important to consider the impact of equipment on tool performance. A good descaling equipment should avoid adverse effects on the temperature and microstructure of the metal tools during the descaling process. If the equipment causes a significant drop in the tool's temperature, it may affect subsequent processes such as forging and heat treatment; altering the microstructure will reduce the strength and hardness of the tool. The equipment of LITAI Technology can control the temperature difference of the workpiece within 35℃, without changing the microstructure, and can effectively avoid these problems.

Finally, weigh the cost of the equipment and its ease of maintenance. Besides the purchase cost of the equipment, operating costs such as energy consumption and water fees should also be considered. At the same time, the ease of maintenance of the equipment is also very important. Whether it is convenient to replace worn parts and how high the maintenance cost is, all these will affect the long-term use of the enterprise. Choosing equipment with high cost performance and convenient maintenance can reduce the production and operation costs of the enterprise.

In conclusion, when choosing an appropriate equipment for removing oxide scale from hardware tools, a comprehensive assessment should be conducted by considering factors such as the tool's characteristics, production efficiency requirements, impact on tool performance, and cost, in order to select the equipment that best meets the production needs of the enterprise.

Related News