Hot forging to remove the oxide scale has always been a difficult problem in forging plants

发布时间:

2024-04-02

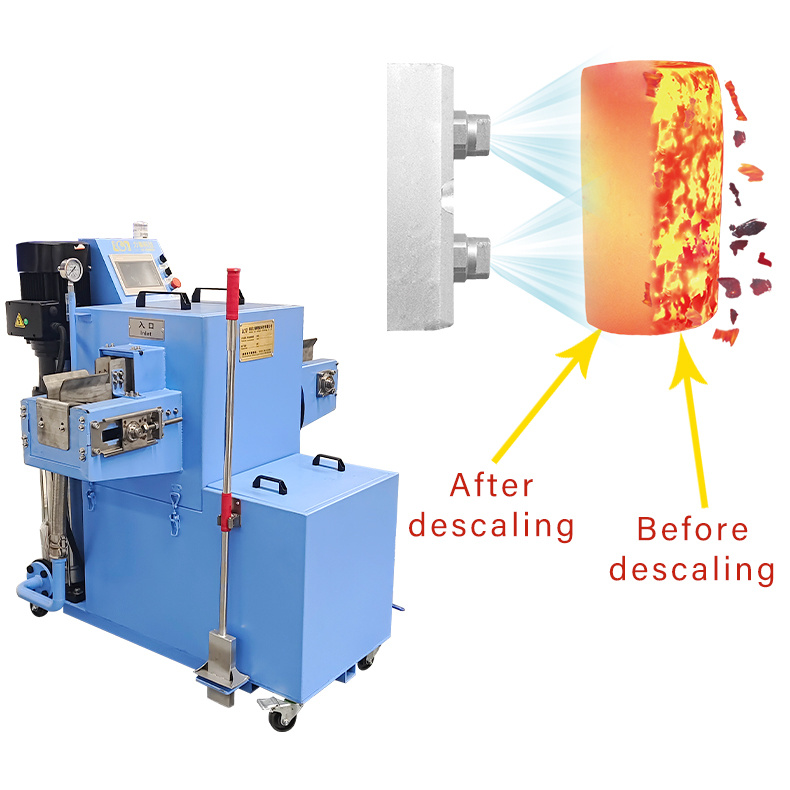

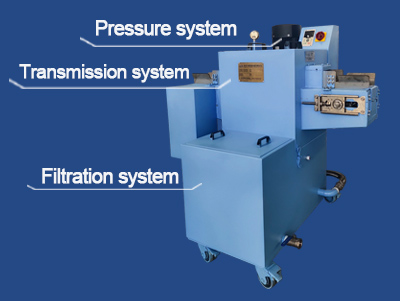

Hot forging to remove the skin is always a difficult problem in forging plants. Various forging plants use different methods of hot forging to remove the skin. Some use pickling, some use upsetting, some use mechanical hot forging to remove the skin, in short, a variety of hot forging to remove the skin. Until the appearance of hot forging deoxidizing machine, the principle of high pressure hydrothermal forging deoxidizing can remove the oxide on the surface of the forging, improve the quality of the forging, reduce mold wear and improve the service life of the mold.

There is almost no temperature difference before and after the forging machine is cleaned, which can be ignored and will not affect the mirror structure of the forging. Hot forging deoxidizing machine adopts the principle of high pressure water hot forging. In the hot forging deoxidizing system, the high pressure water produced by the high pressure pump enters the nozzle of the hot forging deoxidizing device.

Under the action of the nozzle, the high-pressure water forms a strong impact fan jet, which is sprayed to the surface of the billet (or medium billet). Under the action of high-pressure fan water jet, the oxidation sheet is cut, quenched and shrunk, stripped from the matrix, and the oxidation sheet is washed off the surface of the billet (or intermediate billet), so as to clean the oxidation sheet. Strengthen operation adjustment to prevent overheating of heating surface. When the unit starts and stops, the change rate of heating surface temperature and pressure should be strictly controlled. It is forbidden to stop the furnace for forced cooling, and try to avoid frequent starting and stopping of the unit.

During operation, the load change rate of the unit should be properly controlled, the thermal deviation of the heating surface under high temperature should be monitored and adjusted, so as to prevent long-term local overheating of the heating surface and slow down the generation of deoxidizing skin of the gas stove. The manual adjustment of the superheater and reheater desuperheater should be carried out smoothly to avoid drastic changes in the water volume of the desuperheater and the peeling of the oxide skin resulting in a sharp drop in the temperature of the tube wall of the superheater and reheater. Before the steam soot blower is put into use, the heating and drainage of the pipeline should be strengthened to prevent the heating surface pipeline from being rapidly cooled by the water brought by the steam and prevent the scale from falling off.

The hot forging deoxidizing machine is used in the hot forging state, so the bar forgings are easy to produce oxide skin during the heating process, which is caused by the high hardness of the forgings and the uneven distribution of the blank surface. The mold will wear faster, the manufacturing cost of the mold itself is high, and the product will wear out surface defects in post-processing, so the raw material size before heating is larger than the budget, and it is necessary to hire people to do machining operations. This undoubtedly increases the cost of raw materials and labor in the forging industry. Fortunately, the hot forging deoxidizing machine has removed the oxide in the hot forging process, and if this part of the oxide is not removed before forging, it will cause unnecessary wear to the mold, resulting in faster mold wear, and the mold itself is high manufacturing cost, which increases the production cost virtually. Therefore, improving the skin on the surface of the bar before forging is far higher than the cost reduction and efficiency brought about by shot blasting and sandblasting in the later stage.

Hot forging to remove the skin is always a difficult problem in forging plants. Various forging plants use different methods of hot forging to remove the skin. Some use pickling, some use upsetting, some use mechanical hot forging to remove the skin, in short, a variety of hot forging to remove the skin. Until the appearance of hot forging deoxidizing machine, the principle of high pressure hydrothermal forging deoxidizing can remove the oxide on the surface of the forging, improve the quality of the forging, reduce mold wear and improve the service life of the mold.

There is almost no temperature difference before and after the forging machine is cleaned, which can be ignored and will not affect the mirror structure of the forging. Hot forging deoxidizing machine adopts the principle of high pressure water hot forging. In the hot forging deoxidizing system, the high pressure water produced by the high pressure pump enters the nozzle of the hot forging deoxidizing device.

Under the action of the nozzle, the high-pressure water forms a strong impact fan jet, which is sprayed to the surface of the billet (or medium billet). Under the action of high-pressure fan water jet, the oxidation sheet is cut, quenched and shrunk, stripped from the matrix, and the oxidation sheet is washed off the surface of the billet (or intermediate billet), so as to clean the oxidation sheet. Strengthen operation adjustment to prevent overheating of heating surface. When the unit starts and stops, the change rate of heating surface temperature and pressure should be strictly controlled. It is forbidden to stop the furnace for forced cooling, and try to avoid frequent starting and stopping of the unit.

During operation, the load change rate of the unit should be properly controlled, the thermal deviation of the heating surface under high temperature should be monitored and adjusted, so as to prevent long-term local overheating of the heating surface and slow down the generation of deoxidizing skin of the gas stove. The manual adjustment of the superheater and reheater desuperheater should be carried out smoothly to avoid drastic changes in the water volume of the desuperheater and the peeling of the oxide skin resulting in a sharp drop in the temperature of the tube wall of the superheater and reheater. Before the steam soot blower is put into use, the heating and drainage of the pipeline should be strengthened to prevent the heating surface pipeline from being rapidly cooled by the water brought by the steam and prevent the scale from falling off.

The hot forging deoxidizing machine is used in the hot forging state, so the bar forgings are easy to produce oxide skin during the heating process, which is caused by the high hardness of the forgings and the uneven distribution of the blank surface. The mold will wear faster, the manufacturing cost of the mold itself is high, and the product will wear out surface defects in post-processing, so the raw material size before heating is larger than the budget, and it is necessary to hire people to do machining operations. This undoubtedly increases the cost of raw materials and labor in the forging industry. Fortunately, the hot forging deoxidizing machine has removed the oxide in the hot forging process, and if this part of the oxide is not removed before forging, it will cause unnecessary wear to the mold, resulting in faster mold wear, and the mold itself is high manufacturing cost, which increases the production cost virtually. Therefore, improving the skin on the surface of the bar before forging is far higher than the cost reduction and efficiency brought about by shot blasting and sandblasting in the later stage.

Related News