Litai analyzes the advantages of the hot forging bolt process

发布时间:

2024-04-29

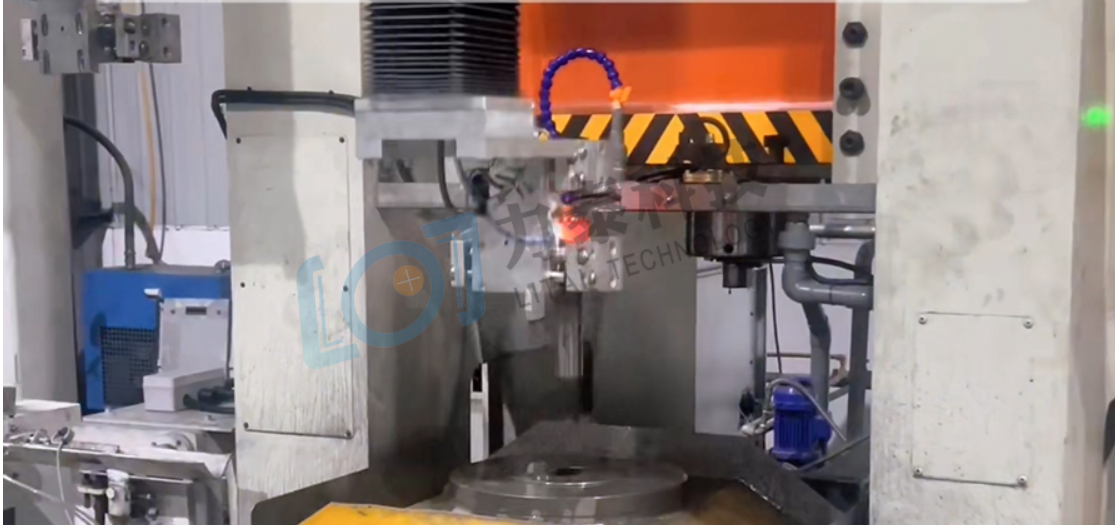

Hot forging bolt is a common forging process, which is a forging method in which metal ingredients are hot processed at high temperature to form the desired shape under the action of force. Hot forging bolt is a common forging process, which is a forging method in which metal ingredients are hot processed at high temperature to form the desired shape under the action of force. Bolt hot forging is suitable for the production of bolts, nuts and high-strength bolt connectors of various shapes. Free forging is an advanced metal plastic forming process, which is to place metal ingredients in the forging die and achieve metal forming by applying pressure without restriction. In contrast, bolt hot forging is the use of hot processing to achieve metal forming, casting, die forging, cold forging and powder extrusion are also metal plastic forming methods.

Hot forging bolts have the following advantages:

1, with good formability, can produce higher precision, higher quality parts;

2, low cost, compared with cold forging and other processes, bolt hot forging production cost is lower;

3, wide range of application, not only for steel, but also for copper, aluminum, magnesium and other materials forming. Therefore, bolt hot forging is widely used in the manufacturing industry, especially in the automotive, machinery, aviation, aerospace and other fields.

In summary, although hot forging bolts do not belong to free forging, they have good formability and a wide range of applications. By choosing the correct forging die and operation skills, higher precision and higher quality bolt connectors can be obtained, which has very important practical significance. Bolt hot forging is suitable for the production of bolts, nuts and high-strength bolt connectors of various shapes. Free forging is an advanced metal plastic forming process, which is to place metal ingredients in the forging die and achieve metal forming by applying pressure without restriction. In contrast, bolt hot forging is the use of hot processing to achieve metal forming, casting, die forging, cold forging and powder extrusion are also metal plastic forming methods.

Hot forging bolts have the following advantages:

1, with good formability, can produce higher precision, higher quality parts;

2, low cost, compared with cold forging and other processes, bolt hot forging production cost is lower;

3, wide range of application, not only for steel, but also for copper, aluminum, magnesium and other materials forming.

Therefore, bolt hot forging is widely used in the manufacturing industry, especially in the automotive, machinery, aviation, aerospace and other fields.

In summary, although hot forging bolts do not belong to free forging, they have good formability and a wide range of applications. By choosing the correct forging die and operation skills, higher precision and higher quality bolt connectors can be obtained, which has very important practical significance.

Related News